Pressmeddelande -

Optimized crop flow and front-mounted chopper ex factory for CLAAS QUADRANT EVOLUTION

New performance features for CLAAS square balers

Optimized crop flow and front-mounted chopper ex factory for CLAAS QUADRANT EVOLUTION

Harsewinkel/Metz-Woippy, 11 August 2022.

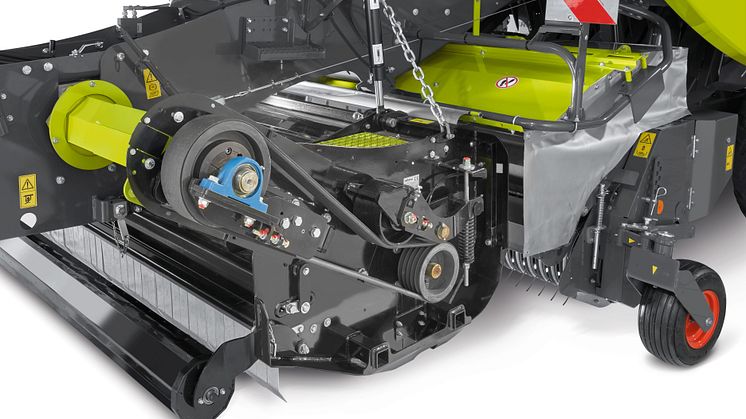

For the 2023 season, the QUADRANT EVOLUTION launched in 2021 will have a new drive train with a further developed flywheel, and can also be factory-equipped with a new front-mounted chopper from Müthing. Another innovation is the hydraulic drive of the pickup and POWER FEEDING SYSTEM.

20 Years CLAAS QUADRANT FINE CUT

The CLAAS QUADRANT has become one of the best-selling square balers in Europe since its introduction in 1988. In addition to the high stability and reliability of the machines, customers particularly value the low operating costs. CLAAS QUADRANT square balers are in use all over the world – from baling conventional crops such as barley and wheat straw or hay and grass silage to corn straw and sugar cane.

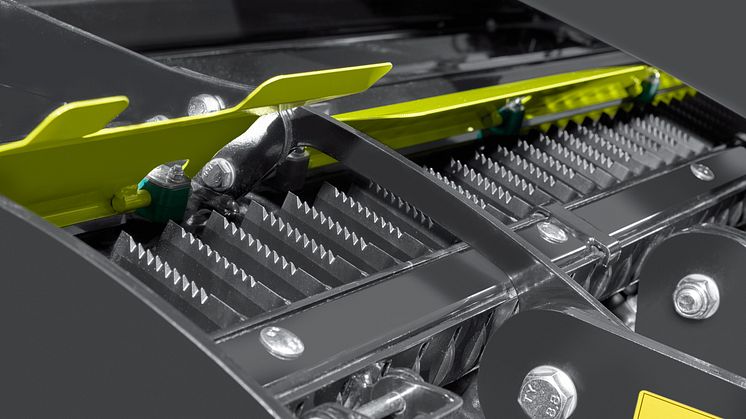

In 2002, exactly 20 years ago, CLAAS introduced the pioneering and successful FINE CUT technology to the QUADRANT series. With initially 49 and later 51 knives instead of the usual 25 on the ROTO CUT, an unrivaled theoretical cutting length of just 2 cm could be achieved. The result was easier bale breakup when littering, a higher bale density and direct use as litter for poultry houses and dairy cow cubicles - i.e. tradable short straw. Thanks to its shorter chop length, FINE CUT straw is significantly more absorbent than conventionally chopped straw.

Hydraulic drive for pickup and PFS feed roller

The QUADRANT EVOLUTION series presented in 2021 comprises the three basic models 4200, 5200 and 5300. For model year 2023, the QUADRANT 5200 and 5300 types will have a hydraulic drive for the pickup and POWER FEEDING SYSTEM (PFS). While the speed of the 5-row pick-up, which is controlled on both sides, is constant at 135 rpm, the speed of the PFS feed roller can be adjusted from 200 to 250 rpm depending on the operating conditions. The increased transmittable torque of the hydraulic drive of 1,000Nm is also fully available for reversing the pickup and PFS at reduced speed.

Another new feature is the hydraulically fully automatic folding pick-up guide wheels. These swing out automatically when the pick-up is lowered and swing in fully automatically when the pick-up is raised. This means that prior to driving on the road, the driver does not have to dismount to manually fold in and lock the guide wheels.

More flywheel mass, fewer peak loads

To cushion load peaks, especially when baling irregular swaths, to protect the power train of the baler and tractor, and thus protect the power train of the baler and tractor, the mass of the flywheel on the QUADRANT 5200 and 5300 has been increased by 21 and 28 percent respectively. Due to the new spoke design, the inertia of the flywheel has been increased by 46% on the QUADRANT 5200 and 44% on the QUADRANT 5300. In order to effectively protect the drive against overload in extreme situations, a slip clutch which provides optimized automatic overload protection can be ordered as an alternative to the standard shear bolt protection.

Front chopper ex works

On request, the QUADRANT 5200 and 5300 can be factory-fitted with a new Müthing front-mounted shredder from model year 2023. The technology offers numerous advantages, especially for contractors:

- § There are no excess stem lengths in the bales as the straw is chopped and not cut.

- § The desired chop quality can be set using the shearbars.

- The front chopper expands the range of uses of the square baler.

The rotor, which is supported on both sides by two-row, solid spherical roller bearings, works with 88 oscillating knives and is driven by a power belt on the left side of the machine. The cutting length can be steplessly adjusted using two adjustable counter blades, each with 45 knives. The blades of the rotor and shearbars can be used on both sides, thereby significantly reducing wear costs and resource consumption. When the front-mounted chopper is active, the crop flow is fed directly to the rotor via the roller crop press of the pick-up. The crop flow can be centered in the direction of the cutting rotor using adjustable guide plates in two available sizes. Pendulum flaps at the front offer effective protection against stone chips.

Transport wheels are supplied as standard accessories. These allow the front-mounted shredder to be disassembled and assembled in less than 20 minutes. Another advantage of the ex-factory solution: all wear and attachment parts for the front-mounted shredder can be obtained from the CLAAS spare parts department.

All features and innovations at a glance:

- Hydraulic drive of pickup and POWER FEEDING SYSTEM for QUADRANT 5200 and 5300.

- Hydraulic and automatic folding of pickup guide wheels.

- New heavier flywheels and, thanks to the new spoke design, increased inertia for QUADRANT 5200 and 5300 to smooth out peak loads.

- New overload protection for QUADRANT 5200 and 5300 flywheels.

- New Müthing front-mounted chopper with 88 reversible knives available ex works.

- New water wash tank, new storage box and new tool box.

You can download high-resolution images for this press release here:

https://dam.claas.com/pinaccess/showpin.do?pinCode=WDpwYKZYRV2z

Please note the following in your journalistic work:

This is an international press release. The product range and feature options may vary in some countries. Please ask the CLAAS sales company or the CLAAS importer in your country in case of doubt.

Press picture archive at claas-group.com

Visit our online press photo archive. A wide range of pictures is available for use in your journalistic reports, free of charge, at: www.claas-group.com > Picture archive

About CLAAS

CLAAS (www.claas-group.com) is a family business founded in 1913 and is one of the world’s leading manufacturers of agricultural machinery. The company, with Head Office in Harsewinkel, Westphalia, is the world market leader for forage harvesters. CLAAS dominates the European market in another core segment as well – combine harvesters. CLAAS also holds the top spots in global agricultural technology with its tractors as well as its agricultural balers and grassland harvesting machines. Cutting-edge agricultural information technology also forms part of its product range. CLAAS employs more than 11,900 staff worldwide and in 2021 generated a turnover of 4.8 billion euros.

Ämnen

Kategorier

Swedish Agro

Swedish Agro är ett svenskt företag som förser lantbrukare med insatsvaror, foder och maskiner av högsta kvalitet. Företaget representerar CLAAS, HORSCH, METSJÖ, RAUCH, SPEARHEAD, SCANSTONE och AVR i Sverige. Service och reservdelar finns mobilt och på 24 orter både via egna anläggningar och servicepartners. Med en av Europas modernaste foderfabriker tillverkas foder för flera djurslag. Swedish Agro är ett företag i Danish Agro-koncernen som består av en rad företag inom lantbruksbranschen i norra Europa.